產(chǎn)品類別

銅導線與垂直接地棒焊接過程

Making a CADWELD joint is a simple procedure as illustrated below:

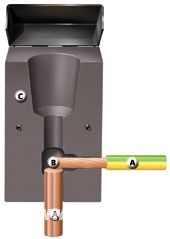

1 Locate the conductors (A)

1 Locate the conductors (A)

to be joined in the weld

cavity (B) and close

the mould (C).

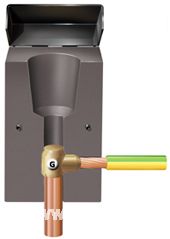

2 Locate the steel retaining disc in

2 Locate the steel retaining disc in

the base of the crucible (D). Pour

in the weld powder (E) followed

by the starting powder (F).

Ignite starting powder

with a spark gun.

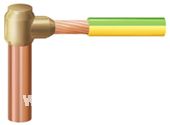

3 The resulting exothermic reaction

3 The resulting exothermic reaction

reduces the weld powder to molten

copper alloy which melts the

retaining disc and flows into

the weld cavity where it partially

melts the conductors (G).

4 The molten copper alloy cools

to leave a fusion weld of great

mechanical and electrical integrity.

CADWELD Moulds

The CADWELD system of exothermic welding uses moulds to contain the exothermic reaction that creates safe and robust connections. Different types of moulds are available, whose use depends on the requirements of the project.

Graphite Moulds

Market leading CADWELD graphite moulds are extremely robust and capable of producing over 75 connections each.

Mini-Moulds

CADWELD mini-moulds are a cost effective alternative to full-sized moulds, especially where lower numbers of connections are required. They are smaller overall, less robust and therefore lower priced. Care is required in order to achieve similar service lives to full-sized moulds.

SureSHOT

The CADWELD SureSHOT system is a single-use ceramic mould supplied complete with retaining disc and powders. It has been designed for use in applications where only a few connections are required. For more information CLICK HERE

| 上一篇:機房防靜電接地及等電位連接下一篇:常見的放熱焊接形式(火泥熔接) |

豫公網(wǎng)安備41019702003907號

豫公網(wǎng)安備41019702003907號